A huge array of quantitative and qualitative techniques is used by market analysts including in-depth interviews, ethnography, customer surveys, and analysis of secondary data. Important insights, as well as findings, latest key drivers, and constraints, are also depicted here. įlason at the same time provides more advanced products and fast technical support for global customers domestically and at abroad ( including Germany, India, Brazil, Vietnam ) has multiple marketing centers and technical support centers in the world, and many agent partners world-widely.įlason Electronic Co.New Jersey, United States – The Reflow Oven Market research report aims at providing a quick overview of the overall performance of the industry and significant novel trends. Currently Flason SMT machine represent the highest level and maintain absolute technological lead in China.Īt the end of 2012, Flason declared and approved a total 30 patents ( including four invention patents ), and actively participated in a number of national and industry standards -setting, making the standard and patent closely. Our core team consists of industrial experienced experts from Harbin Institute of Technology, siemens and other companies institutions,combined top international technology with independent R&D, overseas R & D center in shenzhen put into use in August,2013. SMT reflow oven, soldering oven, SMT oven, SMT soldering reflow oven, smt assembly line reflow oven, PCB soldering reflow oven, SMT assembly oven, PCB soldering oven, LED reflow oven, LED PCB reflow oven.įlason Electronic Co ltd is high tech smt assembly line Manufacturer, focusing on SMT assembly line equipment research and development,building new advanced solutions in SMT assembly line, LED Production line, semiconductor assembly line, energy machines assembly line and other areas.

#Btu reflow oven software

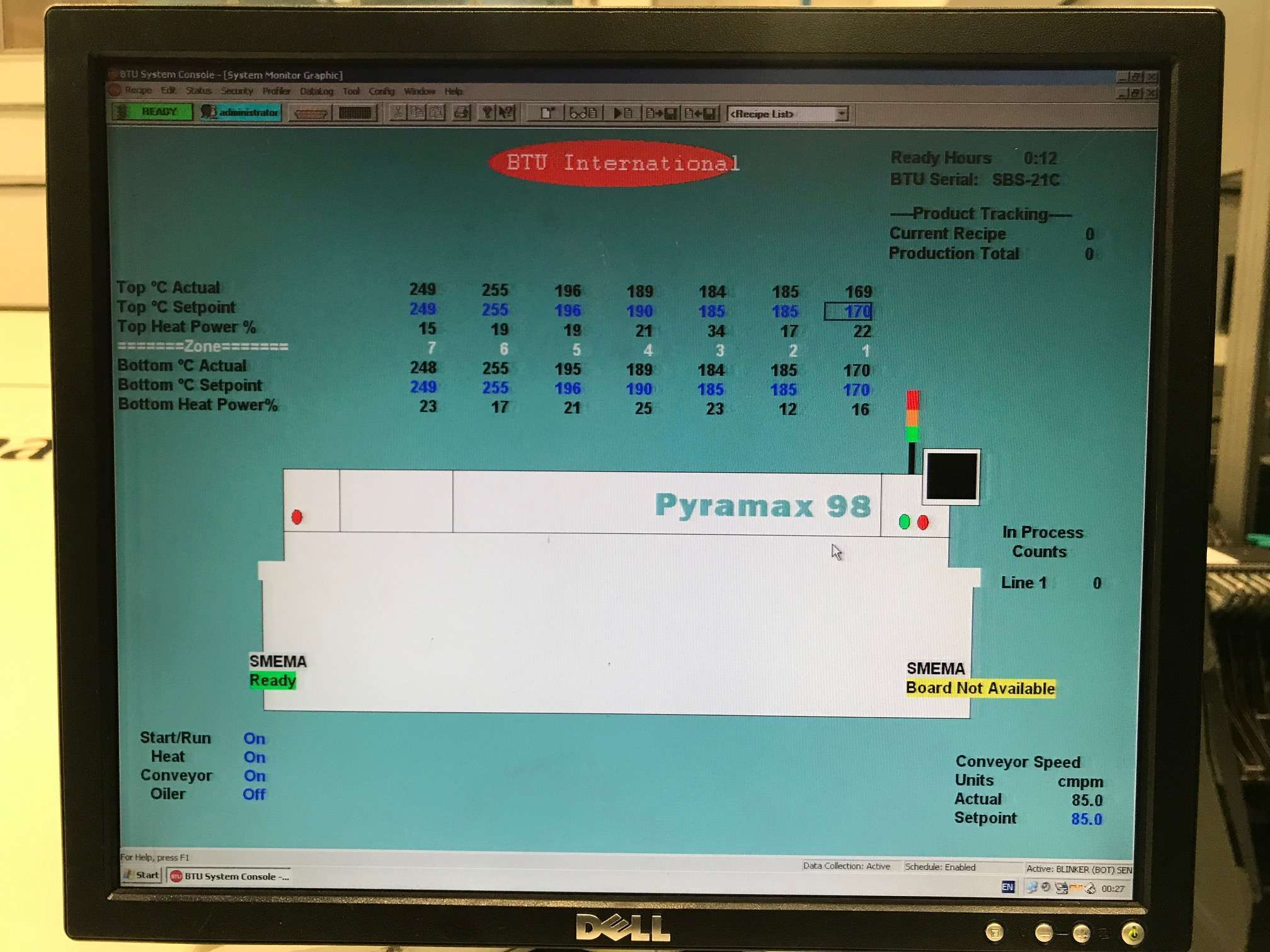

To enhance uptime the Pyramax is supported by BTUa s 24-hour, 7-DayWorldwide customer support, electronic user documentation, and Parts Identification Software which allows customers to identify parts without the use of a cumbersome paper manual.įlason SMT are long term and stable supplier of above stated SMT parts.įlason SMT will Provide high quality and low price goods and perfect follow-up service.

Water cooling features a sliding heat exchanger assembly allowing easy access for maintenanceĬlosed loop cooling control provides variable cooling rates and increased process controlīTUa s repeatable process control eases the transition to lead-free.Įlectronic Over-Temperature Safety SystemīTUa s quality products are backed by its Industry leading comprehensive warranty.

Multiple extraction locations maximize overall efficiencyĪ On the flya maintenance eliminates downtimeīTUa s unique clamshell air or water-cooling design moves the cooling media away from the process chamber, where it can be easily accessed for maintenance. Unmatched convection efficiency reduces zone temperature setpoints.īTUa s patented Flux Management System traps flux residue from the process chamber, preventing it from settling within the oven, leading to increased uptime and lower cost-of-ownership.Įasy access to filtration and trap arrangement Guaranteed process repeatability, system to system, site to site Side-to-side recirculation enhances temperature uniformity With 6, 8, 10 and new 12-zone air or nitrogen models, 350oC maximum temperature and a comprehensive menu of options, Pyramax systems are the industrya s most versatile performers and best value.īTUa s exclusive Closed Loop Convection Control provides maximum flexibility in process control. BTUa s exclusive closed loop convection control provides precise heating and cooling, programmable heat transfer, and reduced nitrogen consumption, adding up to the lowest Cost of Ownership in the industry. Pyramax systems provide optimized lead-free processing for the ultimate in productivity and efficiency.

BTU Pyrama family of high-throughput thermal processing systems is widely recognized as the global standard of excellence for both printed circuit board solder reflow and for semiconductor packaging.

0 kommentar(er)

0 kommentar(er)